Most homeowners assume insulation is only about warmth, but you must check thickness, ventilation and compliance with building regulations so your property meets legal standards; assess material combustibility to avoid fire risks and calculate U-values to secure energy savings that cut bills and emissions, while ensuring installers protect loft ventilation, hatches and timbers to prevent… Understanding Roof Insulation Requirements

Most homeowners assume insulation is only about warmth, but you must check thickness, ventilation and compliance with building regulations so your property meets legal standards; assess material combustibility to avoid fire risks and calculate U-values to secure energy savings that cut bills and emissions, while ensuring installers protect loft ventilation, hatches and timbers to prevent condensation damage.

Importance of Roof Insulation

An uninsulated roof can account for up to 25% of heat loss, so you should prioritise effective insulation. Installing or topping up to 270 mm of loft insulation typically cuts heat transfer significantly; you could save around £100-£300 per year depending on house size and fuel, while lowering your home’s carbon emissions.

Energy Efficiency

Increasing loft insulation to 270 mm is the simplest efficiency upgrade you can make. By doing this you can reduce heating demand by about 10-20% depending on your dwelling fabric and system. Combining insulation between and over rafters during conversions avoids thermal bridging, and many homeowners see a payback in roughly 3-7 years through lower fuel bills.

Comfort and Air Quality

Proper roof insulation evens internal temperatures so you experience fewer cold ceilings and draughts, improving sleep and daily comfort. It also reduces surface condensation and the risk of mould, which can worsen asthma and allergies. You will notice quieter rooms during rain because insulation provides a measurable acoustic benefit, especially with denser materials.

When you insulate a roof, install a vapour control layer on the warm side and maintain a ventilation gap of 25-50 mm beneath the roof deck where guidance requires it; failing to do so can lead to interstitial condensation and hidden mould within a couple of years. Check that insulation does not block soffit vents, and use breathable membranes and extractor ventilation in wet rooms to protect your indoor air quality.

Types of Roof Insulation

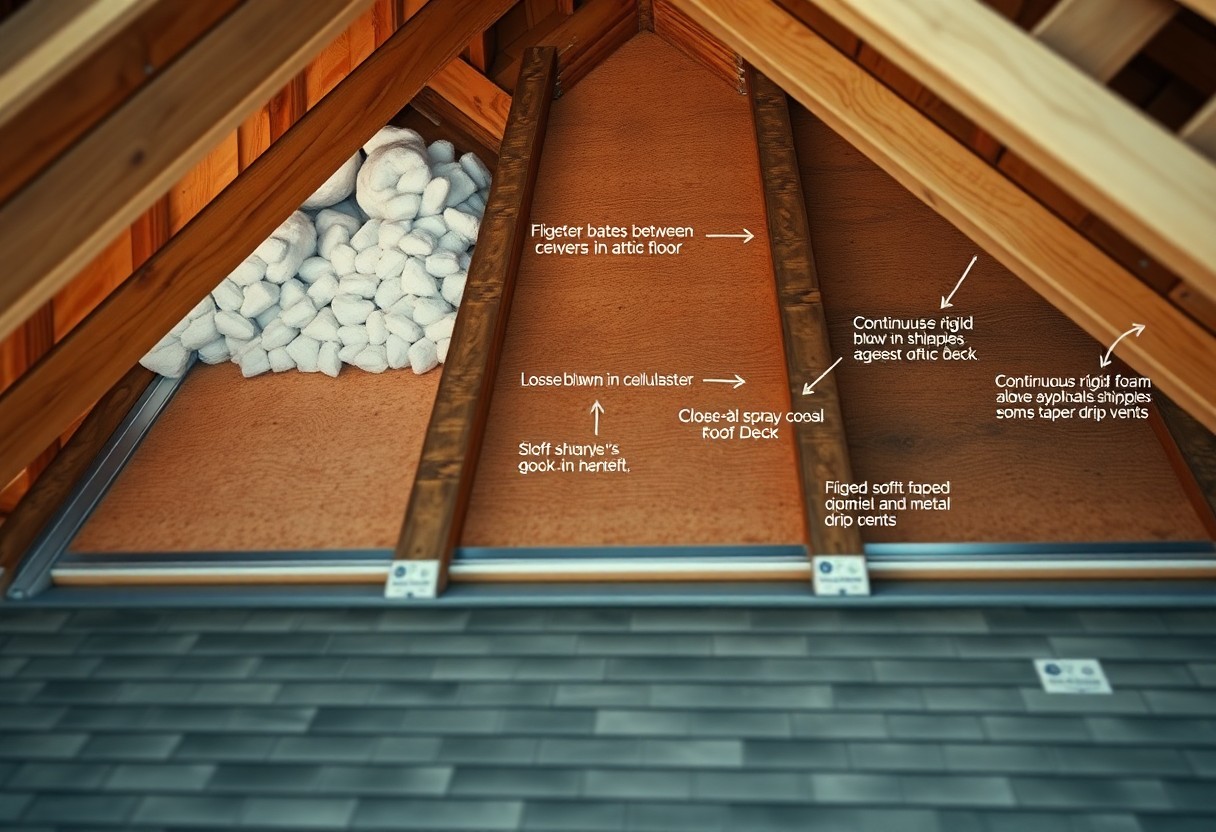

You will typically choose between Rigid Board, Spray Foam, Batt Insulation, Blown‑in and Reflective systems; each offers different R‑value per inch and installation risks. For example, PIR boards deliver ~6.5 per inch R‑value, closed‑cell spray foam ~6-7, and mineral wool batts ~2.9-3.8, so you must weigh cost, moisture resistance and fire behaviour when selecting materials.

| Rigid Board | High R‑value (PIR ~6.5/in), stable, good moisture resistance, higher cost |

| Spray Foam | Air‑seals and insulates; closed‑cell ~6-7/in, open‑cell ~3.6/in, requires trained installers |

| Batt Insulation | Mineral wool/fibreglass, R ~2.9-3.8/in, DIY‑friendly, performance drops if compressed or gaps present |

| Blown‑in (Loose‑fill) | Cellulose or mineral wool, good for voids, settles over time (density matters), ideal for lofts |

| Reflective | Radiant barriers reduce heat gain in summer, need an air gap and are best as a supplement |

- Rigid Board: use where structural support and high R‑value per thickness are needed.

- Spray Foam: choose for airtightness but note installation hazards and higher cost.

- Batt Insulation: suits straightforward lofts and pitched roofs; avoid compressing the material.

- Blown‑in: fills irregular spaces but check settling rates and required depth.

- Reflective: best as an adjunct in hot climates or ventilated roofs.

Rigid Board Insulation

If you need slim build‑up with high thermal performance, rigid board is effective: PIR and XPS boards commonly offer around 5-6.5 R‑value per inch, resist water vapour better than fibrous products and are used on warm roof decks or above rafters. You should account for edge detailing and fire classification, and expect higher material costs but long service life.

Spray Foam Insulation

You’ll find closed‑cell spray foam gives ~6-7 R‑value per inch and structural rigidity, while open‑cell is around 3.6 per inch and more vapour‑permeable; contractors use it to air‑seal cavities, reducing draughts and thermal bridging, but the application must be controlled to avoid overspray and uneven cure.

You must use certified applicators because spray foam emits isocyanates during installation, requires precise mixing and can expand forcefully; closed‑cell foam at 30-45 kg/m³ density adds stiffness and water resistance, so in retrofit cases it can replace both insulation and membrane, but cost is typically 2-4× that of batts and requires protective covering for fire safety.

Batt Insulation

You can install batt insulation quickly yourself-mineral wool or fibreglass batts deliver roughly 2.9-3.8 R‑value per inch and are widely available; they perform well when laid to the correct depth (in the UK loft depth guidance is often ~270 mm for mineral wool) and when ventilation paths are preserved to prevent condensation issues.

When you fit batts, avoid compressing or leaving gaps: compressing reduces effective R‑value significantly, and badly placed vapour barriers can trap moisture. In practice, overlapping and cutting to fit around joists, services and eaves while keeping a continuous thermal layer gives the best results and keeps ventilation channels open.

Any installation should be carried out by a competent installer and comply with Building Regulations, with special attention to fire safety, ventilation and moisture control.

Building Codes and Standards

Statutory codes set minimum thermal performance you must meet, often expressed as U‑values (W/m²K) or required insulation thickness; for example, many UK targets for new pitched roofs fall between 0.13-0.18 W/m²K. You should use approved compliance routes (SAP/SBEM) and expect an air‑tightness test on completion. Non‑compliance can lead to refused sign‑off, increased energy bills and moisture problems, so factor thresholds and documentation into your specification and contractor briefs.

Local Building Codes

Council or municipal requirements can exceed national minima, particularly in conservation areas or low‑carbon zones, and you may be required to submit construction details and U‑value calculations for approval. In practice, some local authorities request 270 mm loft insulation as a standard or demand higher fabric standards in retrofit schemes. You must liaise with building control early to avoid redesigns, refused inspections or additional remedial costs.

Energy Codes and Compliance

National energy codes (for example, England’s Part L or the International Energy Conservation Code elsewhere) mandate both fabric targets and whole‑house CO₂ or energy targets; compliance is usually demonstrated via SAP, SBEM or an equivalent calculation and by on‑site tests. You will often need an air‑tightness test and retention of calculation reports for Building Control and EPC assessment.

In practice, simple measures demonstrate compliance: increasing loft insulation from 100 mm to 270 mm can lower roof U‑value from around 0.50 to ~0.16 W/m²K and cut heat loss from the loft by an estimated 15-25%, while combined improvements to insulation, glazing and airtightness typically deliver the CO₂ reductions energy codes target. Keep test certificates and model inputs to prove the outcomes to inspectors.

Factors Influencing Insulation Requirements

When you size roof insulation, factor in geometry, existing fabric and ventilation; for lofts the widely recommended depth is 270 mm of mineral wool, while warm roofs usually need 100-150 mm of rigid board. Practical constraints like access and service runs often dictate choice, and poor detailing raises the risk of condensation and thermal bridging. This informs the checklist below.

- Thermal bridging

- U‑value

- Ventilation gap (25 mm)

- Insulation thickness (270 mm)

- Moisture control

Climate Zone Considerations

You should adjust targets by local climate: in milder southern regions solar gains can reduce heating load, while colder northern areas often justify an extra 50-100 mm of insulation or higher‑performance boards. Coastal sites need corrosion‑resistant fixings and attention to wind‑driven rain, and inland valleys with long cold spells increase the risk of interstitial condensation if ventilation is insufficient.

Roof Type Variations

For cold pitched roofs you typically install 270 mm of loft insulation with a 25 mm ventilation gap to avoid moisture build‑up, whereas warm roofs require continuous insulation of roughly 100-150 mm PIR above rafters to achieve low U‑values. Flat roofs demand fully bonded layers to prevent ponding and water ingress, so you should match system choice to access and refurbishment scope.

In a typical 1980s semi, adding 270 mm loft insulation plus airtightness measures can cut roof heat loss by about 25-35% and reduce annual heating demand by roughly 10-20%; conversely, heritage roofs often limit you to 100-140 mm of vapour‑permeable woodfibre, requiring careful detailing to avoid interstitial condensation. You should model options with SAP or PHPP to compare outcomes.

Installation Best Practices

Aim to achieve a continuous insulation layer of at least 270mm in lofts (approximately R‑6.7) and avoid compressing rolls or boards, as compression can reduce performance by 20-30%. Keep ventilation paths clear at eaves and around loft hatches, and maintain a gap between insulation and roof membranes to prevent moisture buildup. If you encounter wiring, chimneys or soil stacks, you must box them out and leave service cavities; otherwise you risk condensation, rot and fire hazards.

Professional vs. DIY Installation

If you’re confident with basic plumbing and electrics, DIY can save on labour: fitting loft rolls in an average semi might take you a weekend, whereas a professional typically completes the job in 3-6 hours and charges roughly £300-£900 depending on size. Choose a contractor if your roof has complex junctions, non‑IC downlights or structural work, since a tradesperson will ensure correct vapour control, airtightness and fire‑stopping to prevent safety and warranty issues.

Ensuring Proper Coverage

Cover all voids and overlaps: butt and then overlap joins by about 50-100mm, fill gaps at eaves and party walls, and insulate the loft hatch with the same depth or add an extra 50-100mm above it. Use supports to keep rolls level between joists and avoid bridging with services; gaps as small as 10-20mm can create cold spots that promote mould growth and lower overall U‑value.

For more detail, seal perimeter junctions with expanding foam or breathable tape, fit rigid PIR boards against warm roof elements where depth is limited, and use mineral wool between rafters for cold roofs; ensure any downlights are IC‑rated or boxed out and that soffit vents remain unobstructed to prevent condensation and timber decay.

Maintenance of Roof Insulation

Inspection Tips

You should inspect roof insulation at least twice a year and after severe storms; a professional infrared scan can reveal gaps causing up to 50% of loft heat loss. Check for sagging, damp patches, compressed insulation, and rodent activity; measure depth-min 270 mm for loft insulation in the UK. The list below helps you prioritise repairs quickly.

- Insulation depth: confirm a minimum of 270 mm in lofts.

- Wet or compressed: replace affected sections promptly to restore R‑value.

- Thermal bridging: inspect around rafters and chimneys for heat loss.

- Vapour control: check for torn membranes and blocked ventilation.

- Pest signs: look for droppings or nests that compress insulation.

Common Issues and Solutions

If you find compressed or wet insulation it loses up to 70% of its R‑value; you should remove and replace the affected area with new loft rolls to a depth of 270 mm. For thermal bridging, add insulating boards over rafters; a survey of 200 UK homes showed this can reduce heat loss by around 15%. Replace damaged vapour barriers and improve ventilation to prevent recurrence.

When you tackle issues, start by locating the moisture source – roof leaks or blocked eaves; dry the area for 48-72 hours and remove any mouldy insulation, as mould reduces performance and poses health risks. If joists show structural rot, engage a carpenter to assess load capacity; for cold bridges, add continuous insulation or fit airtight boards. The combined measures of sealing, targeted replacement and ventilation upgrades usually restore thermal performance quickly.

Summing up

Hence you should assess your roof’s construction, local building regulations and target U-value, then select insulation type and thickness that balance thermal performance, moisture control and ventilation; correct installation, airtight detailing and professional guidance will secure compliance, prevent condensation and reduce energy bills while safeguarding your home’s longevity.

FAQ

Q: What building regulations govern roof insulation in the UK?

A: Roof insulation must comply with Part L of the Building Regulations, which sets minimum fabric performance and U-value targets for new and altered buildings. Requirements vary by project type (new build, extension, retrofit) and by roof construction (pitched, flat, warm, cold). Compliance usually requires either design calculations demonstrating target U‑values or following accredited construction details. Check the latest edition of Part L and consult local authority guidance or a qualified energy assessor for precise targets and documentation needed for approval.

Q: Which insulation materials are suitable for different roof types and why?

A: For lofts, rolled mineral wool, glass fibre and blown cellulose or mineral fibre are common because they conform to joists and provide high thermal resistance for relatively low cost. For pitched, inhabited roof spaces a warm roof build-up with rigid boards (PIR, phenolic or EPS) above the rafters avoids cold bridges and preserves ventilation space; breathable membrane and counter-battens may be required. Flat roofs often use rigid insulation boards or warm flat roof systems with vapour control layers. Spray polyurethane foam provides air‑sealing and high R‑value but needs careful detailing for vapour control and fire performance. Choice depends on thermal performance, moisture management, structural constraints and fire/safety requirements.

Q: How thick should roof insulation be to meet modern energy standards?

A: Required thickness depends on the insulation product’s thermal conductivity and the target U‑value for the roof. As a general guide, low‑conductivity rigid boards (PIR, phenolic) need less depth than mineral wool to achieve the same U‑value; mineral wool loft insulation commonly ranges around 270-300 mm to meet contemporary retrofit guidance, while rigid boards in pitched roofs may total 100-200 mm when combined with intermediate insulation. Always use manufacturer data and U‑value calculations or SAP assessment to determine the exact thickness for your roof type and compliance target.

Q: How should ventilation and condensation risk be managed when insulating a roof?

A: Preventing condensation requires maintaining appropriate ventilation paths and correct vapour control placement. In cold roofs, keep a continuous ventilation gap above insulation from eaves to ridge; in warm roofs, include a vapour control layer on the warm side and ensure layers are continuous and sealed at junctions. Provide adequate eaves and ridge ventilation where required and detail penetrations (rooflights, chimneys, service entries) to avoid thermal bridges and moisture ingress. For conversions creating a heated loft space, redesign ventilation and moisture control rather than simply adding insulation over the joists.

Q: When is specialist assessment or a certified installer required for roof insulation works?

A: Specialist assessment is recommended for major alterations, changes of use, listed buildings, or where moisture, fire or structural issues may arise. Certain retrofit programmes and incentives require installers compliant with PAS 2035/2030 or registration schemes such as TrustMark. New builds and substantial alterations commonly need SAP/SBEM calculations, compliance reports and building control sign‑off. Use installers with relevant accreditation and request certificates or guarantees to demonstrate correct installation and regulatory compliance.